PPG PERMANIZER™

PPG has utilized the most advanced technology available

PPG is so confident in the quality and performance of this new product that PPG’s Permanizer ™ Plus is backed by a lifetime warranty against cracking, peeling and flaking. The cross linking 100% acrylic resin in the product uses the features found in two-component high performance coatings to form a durable bond in one amazing coat.

Much like a single thread breaks easily and an intertwined rope with-stands much stress, the cross-linked acrylic is far more durable than the conventional acrylic.

PPG PERMANIZER ™ PLUS 100% acrylic paint formula provides a premium, long-lasting exterior finish with a tough, durable film, super adhesion, industry advanced UV protection and dirt, moisture, and tannin resistance–backed by a limited lifetime warranty against cracking, flaking and peeling.

The advanced properties of PPG Permanizer™ Plus are specifically formulated to resist mildew on the paint film and contain a preservative to prevent discoloration by algae.

Permanizer™ Plus exterior paint provides industry advanced UV protection and dirt resistance to keep exterior colors looking like new for years to come. Permanizer™ Plus helps to extend the painting season with application at temperatures as low as 35°F and also provides excellent early moisture resistance.

Super Premium Exterior

Conventional Acrylic

- Shorter service life

- Less protection from elements

- More prone to cracks, flaking and peeling

- Allows tannin’s to escape and discolor the paint film

- Allows water in to damage the substrate

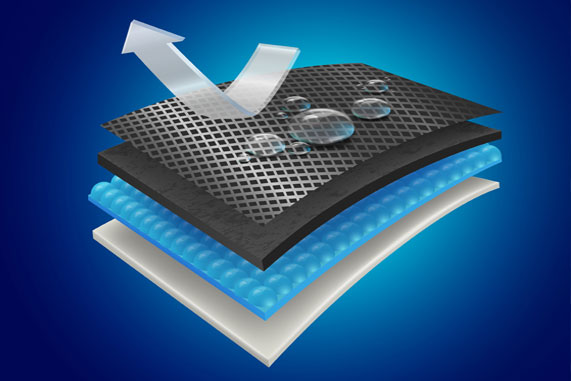

Cross Linked Acrylic

- Extremely durable, long-lasting finish

- Won’t crack, flake or peel

- Superior moisture resistance

- Tannin’s are trapped in the first layer of paint film

- Breathable paint film allows moisture vapors to transfer out

High Film Build

The high film build of Permanizer allows a single application to perform equal to or better than two coats of conventional house paint. The result is a better hiding, longer lasting finish that saves time and money on the job.

Feature

- High volume solids

Function

- Increased film build

Benefit

- One coat coverage

- Better hiding

- Self-priming means less time on the job

- Easily bridges cracks

Film Build Test Method Description

Test paints were applied by brush at natural spread rate to a smooth substrate. A topcoat was applied, if required, by brush at natural spread rate. The panels were allowed to dry at laboratory conditions. When dry, the panels were cut, sanded smooth and photographed at 1 60x magnification.

Bridging Cracks

Surfaces often crack and wear with age. Conventional paints are unable to properly fill cracks and other trouble spots. This allows weather to damage the paint film resulting in cracking, peeling and flaking. The high film build of Permanizer bridges cracks and other trouble spots creating a smooth, uniform, continuous film. This protects the substrate from the elements giving the coating lasting beauty while reducing labor costs associated with treating trouble spots.

Feature

- High volume solids and optimized viscosity

Function

- Increased film build

Benefit

- Bridges cracks of weathered and worn wood

Bridging Cracks Test Method Description

Paints were applied at their natural spreading rate to pre-weathered Tex-ture 1-11 plywood panels. These panels exhibited a significant degree of weathering and surface cracking. No attempt was made to obtain a prede-termined amount of hiding. The paints were allowed to dry in laboratory conditions. Visual examinations for the degree of or ‘bridging’ of the cracks were performed. Photomicrographs at 20X magnification of direct and cross-section views were taken to show the degree of bridging over previously cracked surfaces

Mildew & Algae Resistance Typical Test Method Description

Wooden boards are painted with the coatings to be tested and allowed to dry. The boards are sent to a mildew prone area such as South Florida and exposed at various angles, North Vertical, North Facing 450, and South Facing 45′. Observations of film discoloration are made often. Here, a mildew resistant coating and a coating with minimal protection are pictured

Mildew & Algae Resistance

Unsightly mildew and algae can ruin a beautiful finish. Permanizer has been formulated with 4-way protection from mildew and algae growth. Surfaces should be properly cleaned and treated with PPG Mildew Check’ to insure a mildew free surface prior to painting.

Feature

- Algaecide

- Mildewcide

- Zinc oxide

- Virtually no surfactants

Benefit

- 4-way protection from mildew and algae discoloration

Function

- Resists algae (greenish discol-oration) growth

- Resists mildew spore growth on the paint film

- Disrupts the growth of mildew at the cellular level

- Lack of a common food source for mildew

Exceptional Adhesion

Adhesion is critical to long lasting protection. A chalky surface is one of the most common and difficult surfaces for a coating to adhere. The cross-linking resin in Permanizer TM allows for exceptional adhesion even on a chalky surface.

Feature

- 100% Acrylic Resin self cross linking

Function

- Exceptional adhesion

Benefit

- Sticks to difficult substrates including aged alkyd and chalky surfaces

Adhesion Test Method Description

Wood panels with an alkyd based paint are exposed in Florida until an AST M D-4214 Chalk Rating of 4 to 5 is obtained. These panels are then painted with one coat of the test paint. Each paint is allowed to dry for approximately 16 hours at laboratory conditions. An “X” is inscribed in each test paint and a tape pull adhesion is performed on each sample according to ASTM D-3359. Degrees of failure are noted by the amount of paint removed by the tape.

Early Water Resistance

Sometimes rain or dew formation shortly after painting can cause blisters. Bubbles or blisters on a coating are indicative of a local loss of adhesion. The paint film lifts from the underlying surface. Early blistering will lead to paint failure by peeling. The excellent adhesion of Permanizer prevents blisters or wrinkling.

Feature

- 100% Acrylic Resin self cross linking

Function

- A firm barrier against moisture intrusion

Benefit

- An excellent coating appearance with no surface defacement, wrinkling or blistering—excellent durability

Early Water Resistance Test Method Description

Paints are applied, by a 3-mil Bird Film Applicator, to Leneta Form RP-1K (Release Paper). The coatings are cured at laboratory conditions for 24 hours. A drop of water is applied to the dry film. Surface defects (wrinkling, blistering, discoloration, etc.) are noted at 1-minute intervals. After 15 minutes, the water is removed with a dry paper towel. The panels are allowed to dry and each coating is rated for recovery after 1 hour. Wrinkling or blistering of the paint film indicates that the paint is prone to surface defects if exposed to rain or dew shortly after painting.

Exceptional Tannin Resistance

Tannin bleeding is the brownish or tan discoloration on a paint surface due to migration of tannin’s from the wood substrate through the paint film Tannin bleeding can occur on new and old wood when a coating is applied. Two coats of Permanizer will inhibit discoloration caused by tannin bleeding. Although the first coat may show some discoloration, the tannin’s will be trapped and will not migrate to the second coat.

Feature

- 100% Acrylic Resin self cross linking

Function

- Block tannin stains

Benefit

- Maintains original color by minimizing staining from extractive woods such as plywood, cedar, and redwood

Tannin Resistance Test Method Description

Test paints are applied at their natural spread rate to cedar or redwood panels. The paints are allowed to dry overnight and a second coat is applied to the top half of the panel. After an overnight drying period, the panels are exposed to a water mist chamber (Cleveland Condensing Humidity Cabinet) for 8 hours. The panels are removed from the water mist, and evaluated for appearance. Tannin is manifested as darker colored streaks or bleeding on the painted surfaces.

Alkali Resistance

When paints are not alkali resistant, a crust or white salt deposit can form due to leaching from mansory surfaces. Since Permanizer is alkali resistant new or “hot” surfaces do not require a specialized primer.

Feature

- 100% Acrylic Resin self cross linking

Function

- Resistance to efflorescence

Benefit

- Clean paint surface, free of salt deposits or whitening

Alkali Test Method Description

To determine the effect of painting new or “hot” concrete surfaces, the paints are tested for efflorescence. Three-inch circular Plaster of Paris disks are made efflorescence using a mixture of 2 parts Plaster of Paris to 1 part water. After the disks cure, the test paints are applied at the natural spreading rate to the top and sides of the disks.They are allowed to dry for 3 days. Painted disks are placed in a petridish containing 10 milliliters of 1% sodium hydroxide solution, The petridishes are covered and allowed to sit for 3 days. Five milliliters of 1% sodium hydroxide is then added to the petridish and covered for 4 days. The samples are removed from the petridishes and allowed to dry with good airflow for 4 days. The test paints are rated for efflorescence, disintegration and blistering. Ratings of 0 — (10 = no change) are assigned to each test.

Sag Resistance

Permanizer offers one coat hiding, and does not allow drips that run down the film causing an unattractive appearance.

Feature

- High solids and associative thickeners

Function

- High build without running

Benefit

- Fast one coat application without runs or drips

Sag Resistance Test Method Description

Test paints are applied to a Leneta Form 7B —Sag and Leveling Test using a Leneta Anti- Sag Meter. This Meter (drawdown bar) has a series of notches of successively higher clearance ranging from 6 to 18 mils for lower viscosity or 14 to 60 mils for higher viscosity paints. Immediately after the drawdown is made, the chart is hung with the drawdown stripes in a horizontal position like rungs of a standing ladder, placing the thinnest stripe at the top. The charts are allowed to dry in that position. When the film is dry, the thickest stripe that resisted crossing the gap to touch the next lower stripe is noted. (Reference ASTM D-4400)

Flow And Leveling

Paints having high viscosity can produce application challenges. Pemanizer pro-videos thick bodied paint without the “ropiness” of other high film buid products

Flow And Leveling Test Method Description

Test paints are applied to Leneta Form WB — Plain White Chart using a grooved Leveling Test Bar designed to lay down a wet film with parallel ridges. Paints are allowed to dry overnight in a horizontal position. An oblique light source is used to view the cured test paints. The dry draw-downs are placed perpendicular to the direction of the light. Leveling stan-dards are used to obtain a numerical value for the leveling. (Reference ASTM D-4062)

Water Spot Resistance

Surfactants, an additive in some paints, seep out of the paint film upon expo-sure to moisture and cause unsightly streaking and a soapy appearance. Permanizer has been formulated with virtually no surfactants so your coating will look beautiful even if it is exposed to moisture from an unexpected rain shower or late day dew.

Feature

- 100% Acrylic Resin self cross linking

- Virtually no surfactants

Function

- No water spots

Benefit

- Allows painting late in the day when dew threatens

- A beautiful finish in spite of surprise light showers

Water Spot Resistance Test Method Description

Paint, applicator and substrate (3 mil Bird Bar and Leneta Form WB – Plain white chart) are chilled to 40°F. The paint is then applied to the substrate and returned to 40°F to dry. After 2 hours dry, the panel is removed and misted with water for 10 seconds, shaken to remove excess water and returned to 40°F to cure for 24 hours. After curing the panel is inspected for film formation and water streaks.

Brightness

Many coating manufacturers significantly shade their paint to a light gray color to give them more hiding. In contrast, Permanizer achieves its hiding through a high level of titanium dioxide and optimized theology. The brightness of Permanizer increases the products color range and allows the customer to tint clean, pastel colors.

Feature

- High level of Titanium Dioxide

Function

- Ability to tint clean, light colors

Benefit

- Fewer coats required, customer satisfaction

Brightness Test Method Description

The reflectance (i.e. brightness) of each coating was evaluated according to ASTM D-2805. A 3 -mil Bird-type applicator was used to apply each coating to a Leneta Form W13 Plain White chart. The coatings were allowed to cure for 16 hours at ambient laboratory conditions before measurements were taken. A hi her reflectance value indicates a cleaner, brirhter, whiter finish.